Solutions for Current Transformer Testing

The instrument current transformers supply, and isolate, the secondary relays, meters and other instruments, providing the suitable and manageable secondary quantities which are proportional to those in the primary; there are two main basic groups of instrument current transformers, the metering CTs and the protective CTs, which differs in its role and design, but both requires common current transformer testing techniques, to ensure their proper electrical condition and also their proper connection to the rest of the system.

There are several procedures in current transformer testing, with many differences and performance peculiarities but there are some common routine practices that usually cover transformer ratio, burden, polarity, phase deviation, excitation and insulation tests, among other specific testing.

Key features of the test set for suitable current transformer testing

Current transformer testing is performed through simulation of different situations, by injecting the corresponding signals and measuring the corresponding CT behaviour; according to their design, the protection transformers give priority to a very high saturation level (actually, they must carry the fault currents levels without saturation, and so the relays can sense this fault level), but loosing level and angle accuracy, while the metering transformers saturate before, after nominal current, but prioritizing the accuracy in the ratio and angle during normal operating conditions.

Accordingly, the proper current transformer testing in protection and in metering transformers differs not only in the signals levels to test operating conditions, but also in the power required in for the testing equipment, since usually the protection transformers have more difficult access and require greater length of test leads. Therefore, it is highly desirable that the test set can adapt easily and without limitation to the various requirements of high current and power levels, to cover the different current transformer testing, and also that the test set may have a great portability to be placed closer to the transformer, and reduce the power to achieve the high currents required.

The metering CTs needs high accuracy at nominal currents, and therefore a suitable testing of current transformers requires accurate and stable high current simulation which be independent of the possible impedance changes.

In testing current transformers, it is advisable to test the ratio error and phase angle at different percentages of the rated current, including 100% and higher, through high current injection. Besides individual current transformer testing, it is required a complete checking of the whole protective circuit through primary injection, combined with wire verification of the transformer circuits to ensure they are properly connected. Therefore, the need of different test sets is reduced if the high current primary testing equipment can also be used for various current transformer testing tasks, combining in one system all those applications.

The Raptor, a multifunctional substation test system

The Raptor System meet all the previous commented key features; it is a multifunctional system that integrates the current transformer testing – and also the voltage and power transformer testing – with the high current and high voltage capability for the main primary injection applications in substations and switchgear.

In comparison with the big and heavy traditional variac-based equipment, the RAPTOR is designed incredibly smaller and lighter than its predecessors, allowing the portability required for the current transformer testing; the Raptor provides a revolutionary injection technology in a really transportable test unit of only 35 Kg, with automatic and stable regulation of the magnitude injected, DSP controlled.

The modularity of the Raptor provides the capacity to increase the power of the system, when required, adding current slave units, which is performed in a very simple and quick way, thanks to the self-detecting infrared technology and the no need to interconnect the units. Up to three slaves can be added for up to 15,000 A and up to 18-kVA total injection power, to cover the different situations in current transformer testing.

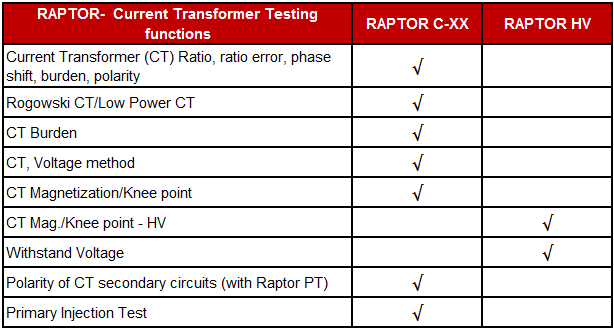

The following chart shows the different applications included in the Raptor System:

An accurate testing of the burden and power factor is important for checking if the transformer is suitable for that burden; the Raptor includes the CT burden measurement from primary and from secondary side. The Raptor also indicates the right or wrong CT polarity through the measurement of the phase shift.The Raptor includes current transformer testing for the ratio through current and voltage method, being preferable the current ratio test. If that is not possible, as in CTs situated directly in the high voltage bushings of power transformers, the ratio can be tested through voltage injection, but it should not be a substitute for current ratio test. The testing at rated current offers more assurance that it will perform as expected when placed in service.

The automatic magnetization test in Raptor uses the IEC criteria for the knee point calculation, and also performs the transformer demagnetization. The Master unit is suitable for any kind of metering CTs, while for the protection CTs which needs higher voltage to saturate, it is required the use of the Raptor HV unit.

The withstand voltage in current transformer testing checks if the transformer dielectric strength is in suitable condition for the service, capable of withstanding overvoltages during operation. The Raptor HV applies the overvoltage between primary and secondary of the transformer, or between secondary and ground, measuring at the same time the leakage current, which will determine if the product will be safe to use under normal operating conditions.

Other EuroSMC equipment for current transformer testing

The PRIME is a new high current micro-ohmeter of EuroSMC, which can be used for measuring the secondary resistance of current transformer winding, provided that the measured resistance is less than 1 ohm, and also as a general purpose contact resistance test set for any connection test of the current transformer secondary circuits.

The PME-20-PH, a digital phase angle meter, is other useful tool for current transformer testing, providing the phase deviation and power factor of the transformer.

The single phase secondary injection unit PTE-100-C can also be used for current transformer testing; thanks to the voltage injection capacity of the PTE-100-C and its integrated measuring functions, it is possible to verify, in manual method, the knee point in a current transformer, provided this is under 250 V; at any case, any of the primary and secondary injection test sets units of EuroSMC, can be used as current and/or voltage sources for current transformer testing, in combination with the suitable external meters.