Testing bars in substation commissioning: a new, modern and efficient method

Due to the great and growing complexity of differential protection schemes, as well as the numerous input and output connections, a large number of parameters must be checked throughout primary and secondary circuits during substation commissioning. This task includes polarity verifications, ratio measurements, identification of protective CTs etc., so substation commissioning must be conducted by skilled personnel using accurate, multi-functional field test equipment.

Traditional substation commissioning methods

Description

Related Products

Additional Information

- Injecting primary current across bars. For substation commissioning, the ideal test current should be as close to the nominal value as possible, but any practically possible current is usually accepted as long as it provides reliable measurements and stable phase angle readings on the secondary side, e.g. on digital relays’ displays. Single-phase current injectors are commonly used to inject the current at the same end of any two phases after placing a jumper connection between the corresponding bars at the opposite end. The same can also be accomplished on a single bar by using the ground or a neutral conductor as the return path. No matter the technique used, the impedance seen by the injector is usually big, and highly inductive, so bulky, heavy injection equipment and a strong power source will be required for the job. Furthermore, the entire process must be repeated three times (one per each single- or two-bar combination), which makes substation commissioning time consuming and hence costly.

- Three phase short circuit. A stand alone generator is used to feed the short-circuited bars with three phase voltage, causing circuit breaker(s) to trip instantaneously. This method proved as a practical alternative for substation commissioning when digital relays started to include a capacity to sample fault signals into voltage, current, frequency and phase angle data, and record them for subsequent collection and analysis. Although the three phase short circuit method is fast and simple, uncertainty about the actual current injected and the risk of damaging system components impose serious drawbacks for its use in substation commissioning.

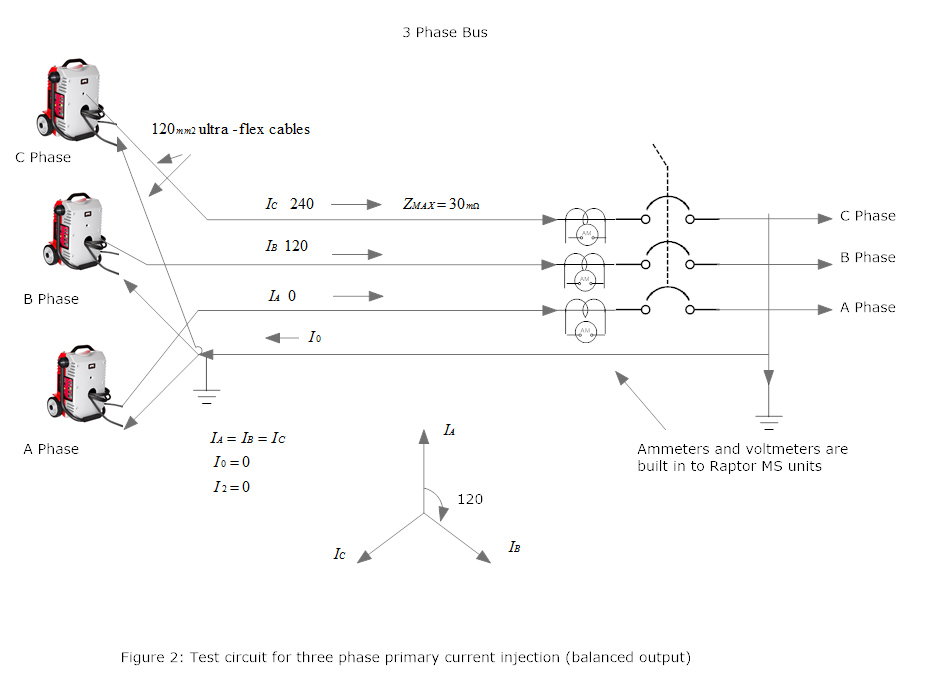

Recommended method for substation commissioning

The TriRaptor will place a stable, significant (e.g. 300A) three-phase current on the busbars for the time it takes for you to examine the readings at digital protective relays or any other primary or secondary measuring devices. This job may take one or two hours when commissioning large substations or bars with numerous input and output links, which should post no problems to the TriRaptor’s permanent injection regime. Furthermore, you won’t really need a huge injection power if you maintain a more or less balanced wye connection with a common return path. With the TriRaptor you can ‘tag’ each phase by using three slightly different current values, e.g. 300A for phase #1, 295A for phase #2 and 305A for phase #3, thus making them much easier to identify and troubleshoot connection, ratio, polarity and phase consistency errors at the secondary equipment’s measurement displays.

The TriRaptor will help you reduce the time for substation commissioning dramatically while increasing accuracy, safety and overall quality of your job.