Choosing a suitable circuit breaker tester

The circuit breaker tester is used to check the operation and condition of circuit breakers on the power systems; for this purpose, the circuit breaker tester applies different signals which are used to test the equipment under a range of system conditions or operation types. At the same time, the circuit breaker tester must have the capacity to capture and measure the specific responses of the DUT to the specific simulation (e.g. trip times, operating sequences, voltage drop, etc) to be able to assess its condition, characterizing the behavior of the DUT to the expected measured magnitude and verify its proper and expected performance; a circuit breaker tester can be also a powerful tool in troubleshooting faulty breakers.

The circuit breaker tester must provide accurate and repeatable results, to be able to compare from previous tests and predict a malfunction of the breaker before it happens. Since the time that the circuit breaker is out of service is short, the circuit breaker tester must provide a minimum set up work and connection time, and minimum test complexity; accordingly, the circuit breaker tester must also be designed for saving test time, providing a unique combination of features that effectively optimize both the results and the methods.

A circuit breaker tester can be specialized for medium/high voltage breakers, or for low voltage breakers, but also a multi-purpose circuit breaker tester can be used for both types as is the case of the high current injection systems and the micro-ohmmeters.

EuroSMC manufactures a comprehensive line of circuit breaker testers for the user to select the most suitable unit for their specific application.

Choosing a suitable circuit breaker tester for the different applications

Circuit breaker tester for timing analysis

The timing test of the different open and close operations of the breaker are performed in factory, in commissioning and during the periodic maintenance; the PME-500-TR is the best circuit breaker tester when analyzing trip times, synchronism and motion parameters of MV/HV circuit breakers; this small and easy to use circuit breaker tester has been designed in close cooperation with our customers and it is a reference used by breaker experts worldwide.

The timing test of the different open and close operations of the breaker are performed in factory, in commissioning and during the periodic maintenance; the PME-500-TR is the best circuit breaker tester when analyzing trip times, synchronism and motion parameters of MV/HV circuit breakers; this small and easy to use circuit breaker tester has been designed in close cooperation with our customers and it is a reference used by breaker experts worldwide.

Apart from the timing, synchronism of the poles, coils condition, mechanical motion analysis and status of the DC batteries, the PME-500-TR includes also the contact resistance measurement of the 3 poles in the same report, saving considerable testing time; this circuit breaker tester is equipped with rechargeable batteries, built-in printer, easy to use touch screen with graphic results, IP67 case, and it is easily transported with just 8 kg and very small size.

Other useful instrument for quick and simple measuring the circuit breaker opening or closing time is the digital timer PTE-30-CH, which is also used for relay and panel testing.

Circuit breaker tester for resistance analysis

The circuit breakers usually carry a large amount of current; higher contact resistance leads to higher losses, lower current carrying capacity and dangerous hot spots in the breaker, so that resistance testing is used for detecting and preventing future problems.

The circuit breakers usually carry a large amount of current; higher contact resistance leads to higher losses, lower current carrying capacity and dangerous hot spots in the breaker, so that resistance testing is used for detecting and preventing future problems.

Contact resistance testing is performed using micro-ohmmeters, which use the four-wires voltage drop method for accurate measurement. EuroSMC offers different solutions for this application:

- PME-500-TR: combining two test sets in one, providing in the same report the timing and synchronization of the circuit breaker poles, and the 3-phase contact resistance measurement.

- New PRIME 600: the top range of micro-ohmmeter in the market, pure DC with smart control up to 600A, also including Dynamic Resistance Measurement, Dual Ground, and wireless remote control. The dynamic resistance measurement is essential in analyzing the wear of the arcing contacts in SF6 breakers.

- RAPTOR: includes a template for contact resistance testing, extending the Raptor System application to its use as high current circuit breaker tester.

High current circuit breaker tester

The analysis of the tripping time characteristics of LV circuit breakers and molded-case circuit breakers is performed using high current injection, as the way to check the entire functionality. Since the circuit breakers are part of the entire protection scheme, it is also essential to check their behavior in the entire protection circuit through primary injection testing. Therefore, the suitable circuit breaker tester must have the capacity to simulate the high current faults required.

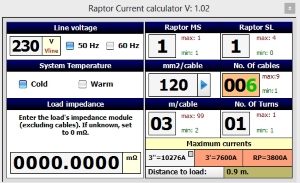

The power of the circuit breaker tester will be defined not only by the maximum current required, but also by the available distance of the DUT to the circuit breaker tester, and the impedance of the whole circuit, which must keep in mind the test leads used and the impedance of the breaker. In this regard, the Raptor is a circuit breaker tester easily upgraded in power capacity to adapt to the different needs. The selection of the proper configuration is now easier with the reliable Raptor Current Calculator, which allows the user to quickly define the Raptor configuration and the number and type of cables required to successfully accomplish the specific high current job. The amazing portability and design of the Raptor System made it the best choice when selecting a multi-purpose circuit breaker tester, being possible to place it closer to the breaker, and reduce the power required.

The power of the circuit breaker tester will be defined not only by the maximum current required, but also by the available distance of the DUT to the circuit breaker tester, and the impedance of the whole circuit, which must keep in mind the test leads used and the impedance of the breaker. In this regard, the Raptor is a circuit breaker tester easily upgraded in power capacity to adapt to the different needs. The selection of the proper configuration is now easier with the reliable Raptor Current Calculator, which allows the user to quickly define the Raptor configuration and the number and type of cables required to successfully accomplish the specific high current job. The amazing portability and design of the Raptor System made it the best choice when selecting a multi-purpose circuit breaker tester, being possible to place it closer to the breaker, and reduce the power required.

EuroSMC also offers traditional variac-based equipment, the LET units, with a wide choice of power ranges, which are also suitable to be used as circuit breaker tester for primary injection applications.

Miniature circuit breaker tester

For smaller current requirements, as in the case of miniature circuit breakers, the wide range of SMC secondary injection test sets are also suitable as circuit breaker tester. The PTE-100-C is able to supply up to 250 A for instantaneous trip time tests, and the PTE-50-CET and MENTOR 12 reach up to 150 A, thanks to their source combination capacity. An specific circuit breaker tester for MCBs in factories and laboratories, is the formed by EMU units in the SMC-12 system, designed to meet the international standards for the routine and quality control tests of MCBs with regards to their thermal and magnetic response.

For more information, please check the related EuroSMC products or contact us.