Testing self-powered reclosers like the S&C Tripsaver II with the Raptor System

Introduction

Testing self-powered reclosers like the S&C TripSaver II is essential to ensure their proper functionality under fault conditions. These reclosers rely on internal current transformers (CTs) and batteries to operate, which poses unique challenges when performing primary injection testing. The Raptor System, a high-performance high current injection test set, provides an effective solution by delivering a stable fault current throughout the testing process.

This article explores the challenges of testing self-powered reclosers and how the Raptor System overcomes these obstacles, ensuring accurate reclose and trip timing.

Challenges in Testing Self-Powered Reclosers

1. Variability in Initial Turn-On Impedance

When performing high current injection tests on a self-powered recloser, an initial challenge arises due to impedance variations.

The TripSaver II wakes up its internal electronics and activates the battery charging circuit when the test current is first applied. This creates an impedance variance that affects the accurate timing of the recloser’s trip and reclose cycles.

2. Cyclic Impedance Variations

During the test, the battery charging system of the self-powered recloser turns on and off in a cyclic pattern. This leads to waveform distortions and current dips in the primary injection system, making it difficult to maintain a steady fault current. In a real-world scenario, these impedance variations are negligible due to the high system impedance of the power grid. However, during testing, where the recloser is the primary load, these variations can significantly affect the test results.

3. Maintaining a Stable Fault Current

All high current injection test sets, including the Raptor System, adjust output voltage to maintain the desired test current. When impedance variations occur, the system compensates by readjusting the voltage. This continuous adjustment is necessary to ensure accurate and reliable recloser testing.

How the Raptor System Solves These Challenges

The Raptor System is specifically designed to address the issues of impedance variation and current instability during self-powered recloser testing. By implementing key adjustments, the Raptor System ensures a stable high current injection test.

1. Increasing Compliance Voltage

One of the most effective solutions is increasing the compliance voltage by adjusting the number of turns through the Raptor System to 7. This increase allows the system to compensate for impedance fluctuations and maintain a consistent fault current.

2. Real-Time Impedance Monitoring

The Raptor System continuously monitors the voltage across the recloser during testing. This allows it to detect impedance variations in real-time and adjust the output current accordingly.

3. Software Enhancements for Self-Powered Reclosers

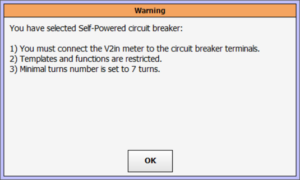

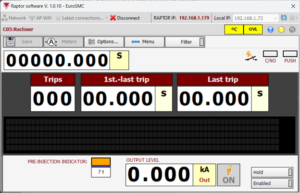

A new software feature in the Raptor Control Program improves testing conditions for self-powered reclosers:

- When connected to the Raptor WA, a new checkbox labeled “Self-powered circuit breaker” appears.

- Selecting this option activates the adjustments needed to maintain a stable high current injection test.

- The system provides on-screen instructions to guide the user in making the necessary test adjustments.

- After activation, the only function available is the Recloser Function, ensuring accurate testing.

With these enhancements, the Raptor System delivers a consistent fault current throughout the test, making it a highly reliable solution for self-powered recloser testing.

Conclusion

Testing self-powered reclosers like the S&C TripSaver II presents unique challenges due to impedance variations and cyclic charging behavior. However, the Raptor System, with its advanced primary injection capabilities and real-time impedance monitoring, provides a stable high current injection solution that ensures precise trip and reclose testing.

By selecting the “Self-powered circuit breaker” option in the Raptor Control Program, testers can confidently perform accurate and efficient recloser tests. This innovation makes the Raptor System an essential tool for utilities and engineers working with self-powered reclosers.

Key Takeaways

✔ Primary injection testing is essential for verifying self-powered reclosers like the S&C TripSaver II.

✔ The Raptor System ensures a stable high current injection, overcoming impedance variations.

✔ New software enhancements allow for easy adaptation to self-powered reclosers, making testing more accurate and efficient.

By leveraging these high current injection test set advancements, engineers can enhance the reliability and performance of recloser testing in real-world applications.