Understanding Reclosers: Types, Applications, and Testing Procedures

Introduction

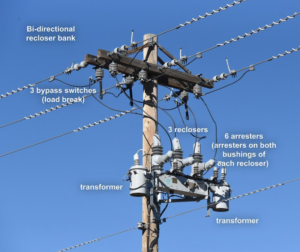

Reclosers are essential components in modern power distribution systems. They function as automated circuit breakers designed to detect and interrupt faults, then automatically restore service if the fault clears. Reclosers significantly enhance grid reliability by reducing outage durations and minimizing service disruptions. These devices are commonly used in overhead distribution networks and substations, playing a crucial role in protecting electrical infrastructure.

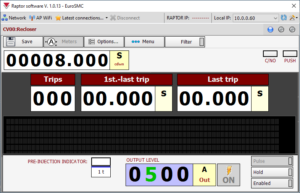

Testing reclosers effectively requires specialized relay testing equipment, including secondary injection test sets, three-phase relay test sets, and single-phase relay test sets, ensuring their functionality under various conditions.

Types of Reclosers

Reclosers can be categorized based on their construction, control methods, and power sources. The primary types include:

1. Hydraulic Reclosers

These traditional reclosers use hydraulic mechanisms to detect overcurrent conditions and operate based on preset trip curves. They are often used in rural and less critical applications.

2. Electronic Reclosers

Electronic reclosers feature solid-state controls that provide greater accuracy, customization, and remote communication capabilities. They are widely adopted in modern smart grid solutions.

3. Vacuum Reclosers

Vacuum reclosers employ vacuum interrupters for arc extinction, making them highly efficient and durable, with minimal maintenance requirements.

4. SF6 Gas Reclosers

These reclosers use SF6 gas for arc quenching, providing high performance in high-voltage applications. However, they require specialized handling and monitoring due to environmental concerns.

5. Self-Powered Reclosers

Self-powered reclosers generate their operating power from line current rather than relying on external power sources. This makes them particularly useful in remote areas and under blackout conditions.

Applications of Reclosers

Reclosers are widely used in various electrical distribution environments, including:

- Rural and Urban Distribution Networks – They help restore power quickly after transient faults and improve system reliability.

- Industrial Power Systems – Used to protect industrial loads from faults and ensure seamless operation.

- Renewable Energy Integration – Reclosers help manage fluctuations in distributed energy resources, such as solar and wind farms.

- Substation Protection – They serve as backup protection devices for power transformers and other critical substation equipment.

To ensure the reliability of these applications, reclosers must undergo rigorous protective relay testing using advanced relay test sets, such as portable relay test sets, automated relay testing tools, and digital relay testing equipment.

Testing Procedures for Reclosers

To ensure optimal performance, reclosers must be tested under controlled conditions. Standard testing procedures include:

1. Operational Timing Test

This test measures the opening and closing times of the recloser to ensure they meet manufacturer specifications. Variations in timing may indicate mechanical wear or control circuit issues.

2. Contact Resistance Test

By injecting a high current and measuring the voltage drop, the contact resistance of the recloser is evaluated. High resistance values may indicate deteriorated or contaminated contacts.

3. Insulation Resistance Test

This test checks the insulation health of the recloser using a megohmmeter to prevent failures due to insulation breakdown.

4. Primary Injection Testing

A high-current injection test simulates real-world fault conditions to validate the recloser’s ability to detect and respond accurately. Relay test units and relay test sets designed for electromechanical relay testing and electrical relay testing ensure precise diagnostics.

5. Secondary Injection Testing

Using a secondary injection test set, this method evaluates the relay’s response without applying full system current, making it ideal for verifying logic settings and control circuits.

6. Control and Communication Testing

For electronic and self-powered reclosers, testing involves verifying remote control functions, SCADA communication, and firmware integrity. This is crucial for modern digital relay testing environments.

Self-Powered Reclosers: Unique Considerations

Self-powered reclosers operate independently by harnessing energy from the line current. Their distinctive features include:

- No External Power Source Required – This makes them highly suitable for remote installations.

- Lower Maintenance Needs – Without battery banks or external power supplies, maintenance costs and failure points are reduced.

- Challenges in Low Load Conditions – Since they rely on line current, extremely low load conditions may impact their ability to function reliably.

- Testing Challenges – Traditional relay test sets may not be directly applicable. Special test setups, such as simulated load conditions, are often required to evaluate their performance accurately.

Conclusion

Reclosers play a vital role in ensuring the reliability of power distribution networks. Their various types, applications, and testing methods help ensure efficient operation and robust protection against faults.

By implementing proper relay testing equipment, including electromechanical relay testing, digital relay testing, and protective relay testing, utilities and maintenance teams can extend the lifespan and effectiveness of recloser systems. Utilizing tools such as secondary injection test sets, three-phase relay test sets, and portable relay test sets enables precise and efficient diagnostics, ensuring the grid remains stable and resilient.

slot gacor 4d

link maxwin

toto slot

toto slot 4d

slot qris

agen toto

toto togel

slot qris

bandar toto

toto slot online

toto slot

slot gacor 4d