Why Relay Testing Is Essential for the Safe Operation of Electrical Substations

Introduction

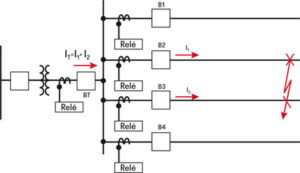

At the heart of every substation lies a vital component: the protection relay. Though small, its role is huge — detecting faults and triggering disconnection before damage occurs. If it fails, the entire installation is at risk.

This is why relay testing is not just a maintenance task — it’s a critical safety measure.

What does relay testing achieve?

Relay testing ensures:

- Correct logic and configuration

- Accurate operating times and settings

- Proper fault simulation responses

- Early detection of configuration or device failures

A protection system that has not been tested cannot be trusted. With increased use of renewables and evolving grid dynamics, regular validation is more crucial than ever.

Recommended testing frequency

The ideal interval depends on how critical the installation is:

- Every 6 months for critical or automated substations

- Once a year for conventional setups

- After any fault, maintenance action, or configuration change

Standards such as IEEE C37.103, NERC PRC-005, and recommendations from manufacturers like SEL suggest that relays should be tested at least annually, and more frequently (e.g., every 6 months) for high-impact or automated systems.

(IEEE Std C37.103-2015, NERC PRC-005-6, SEL AG2000-13)

With modern software like ROOTS, this process can now be automated, reducing human error and saving valuable time.

Recommended equipment for testing

At EuroSMC, we offer a complete range of test systems for manual, semi-automated, or fully automated workflows. Key solutions include:

- Quasar

Our most advanced secondary injection test set, ideal for high-demand, automated relay testing, including IEC 61850 and sequenced workflows with ROOTS.

- ROOTS

Smart control software that automates testing sequences, enhances traceability, and simplifies recurring test plans.

- Mentor 12

Versatile three-phase test set for manual or semi-automated protection testing in any environment.

What happens if you don’t test?

- Undetected faults

- Delayed or failed disconnections

- Personnel and asset risk

- Unexpected downtime

- Loss of compliance or reliability

In short: no testing, no trust in your protection system.

Final thoughts

Relay testing is the foundation of a reliable substation. With advanced solutions like the Quasar and automation via ROOTS, you can ensure precision, repeatability, and peace of mind.