Circuit break timer test set PME-500-TR

Power Circuit Breaker Analyzer

The PME-500-TR represents a breakthrough in the concept of testing, timing and condition-based analysis of medium- and high-voltage circuit breakers and combinations with disconnectors.

Description

Before developing the system or equipment for the testing of a circuit break timer for distribution, the application information was obtained by consulting various users of this type of timer for circuit breaker. The customers consulted were from private service and maintenance companies, large industries, and of course from the Utility companies. It is essential to receive first hand information of the actual requirements and needs of each of these customers who are making these types of tests and then make a detailed study of the various alternatives offered by different manufactures of this type of circuit breaker timer.

All the users that were consulted have timer for circuit breaker of various brands, models, and with various complexities. There was however, a number of requirements expressed by all of those who were consulted, independent of the equipment brand and model they are now using. They were:

- Easy to use

- Contains a built in printer

- Independent on PC

- Reducing the time involved in making these tests and to optimize them

- Improving the quality and accuracy of the results

- Battery operated for the circuit breaker timer

After studying the equipment that now exists on the market and using the points given by the experts interviewed, it was immediately clear why they were unanimous in the requirements given. All the similar units now available on the market, while being of high quality, are not designed for the real situation in the field in testing circuit breakers. The types of timer circuit breaker on the market that have manual control are very difficult to configure and testing a circuit breaker using them is a very slow process.

It is also evident that when testing circuit breakers with timer, as they are usually installed in an open-air environment, the testing conditions are unfavorable. Using a laptop computer for controlling the circuit breaker tester is normally very uncomfortable as a table and a voltage supply is required. Another requirement was the capability to store test results in the actual test equipment.

The PME-500-TR circuit break timer is the solution.

When testing circuit breakers it is essential to have the test results immediately printed so that these results can be observed, analyzed, and the results saved. It is also obvious that the test results from the timer for circuit breaker require additional information, such as identification of the breaker tested, substation, brand, serial number, model, etc., as well as the Type of test, Signal time duration in the coils, along with the actual test results. With ultra-fast, error-free connections to the circuit breaker, and an intuitive, easy to learn graphical touch screen interface with multi-language menus in the PME-500-TR break timer, it dramatically reduces the test time while increasing the analysis accuracy.

The PME-500-TR break timer has a built-in battery that supplies power for 10 hours, eliminating the need for a generator in a shut-down substation, and provides clean, pure DC current for accurate four-wire contact resistance measurement of the three main contacts in a single test.

Besides having a circuit breaker timer which is independent from a voltage supply, the compact size enables the user to have it closer to the object being tested. This allows the connection cables to be shorter from the circuit breaker timer and therefore less susceptible to possible disturbances in the measurement.

Not having to rely on the voltage supply is even more advantageous during commissioning work where generators of poor quality are normally used.

The PME-500-TR break timer is supplied with rapid connection leads and connectors which are very useful in most cases. The use of these cables is recommended as they are electromechanically shielded and immune to disturbances.

The connections of the front panel have been duplicated so cables with standard 4mm banana plugs can also be used. These duplications can be very useful if the special test leads that we provided with the circuit break timer are damaged on site.

The measurement of time, opening and closing coil current consumption, and verification of the contacts are the main requirements when testing circuit breakers. What is missing is the contact resistance measurement which is necessary to determine the current condition of the breaker. This measurement is traditionally obtained from another unit, a micro-ohmmeter. This requires additional time spent with the connections and the results cannot be stored in the same database.

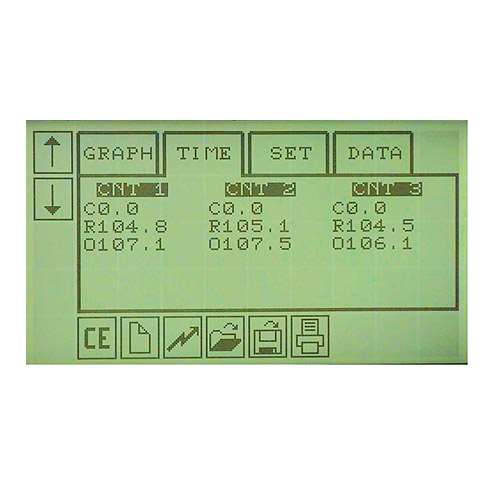

The PME-500-TR break timer automatically measures the contact resistance of the three breaker’s poles at a regulated 10 Adc with a resolution of 0.1 mW and an accuracy of 1%. This low-current micro-resistance measurement is achieved under microprocessor-controlled injection to compensate and cancel the thermocouple effect from the contact surfaces. Furthermore, these results are collected along with the rest of the analysis data, which dramatically reduces off-time in maintenance operations.

An optional plug-in module for the PME-500-TR break timer allows the integration of motion information like travel, speed, acceleration and contact sweep in the test report.

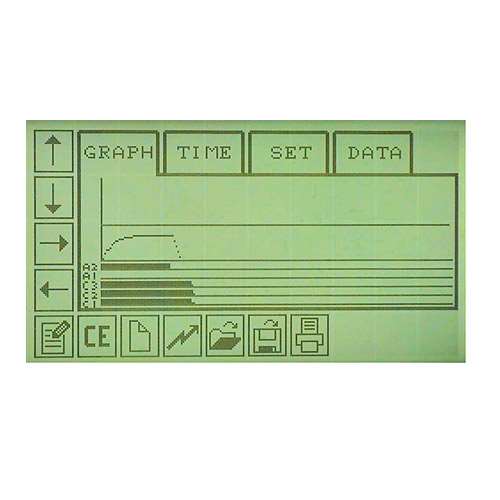

On the front panel of the PME-500-TR breaker timer there is an RS-232 serial port to communicate with an external PC. The circuit breaker timer can be adjusted and calibrated by the calibration software, without the need of opening the equipment. Test results of the analysis done with the PME-500-TR are immediately displayed in tabular and graphical forms, and can be directly output by the built-in thermal printer, saved in flash memory for future re-utilization and downloaded later on to a personal computer for archiving and export to various data interchange formats supplied with the circuit break timer.

CHARACTERISTICS

- 5 time measurement inputs.

- Programmable test sequences:

- C, O, C-O, O-C, C-O-C, O-C-O

- Pure DC injection for contact resistance measurement.

- Test sequence can also be triggered remotely.

- Built in thermal graphic printer.

- Non-volatile storage of up to 60 tests.

- Results can be downloaded to a Windows PC.

- Built-in rechargeable batteries up to 10-hour autonomy.

- LCD touch-sensitive control panel with multi-language menus and graphical results display.

- Test leads & accessories, PC software, transport bag, calibration certificate and user’s manual included.

- Weight: 8 kg.

APPLICATIONS

- Open- and Close-time measurement in main and auxiliary contacts.

- Graphical and numerical evaluation of coil currents.

- Three-phase, 4-wire measurement of contact resistance.

- Substation’s auxiliary DC supply condition evaluation.

more information